Securing our supply chain: Designing for scale up from day one

Disrupted chip supply chains – exposed during COVID-19 – and slow iteration cycles significantly slow research progress in Australia. The COMBS Infrastructure Committee is working to secure diverse fabrication pathways and future-proof microcomb scalability, aiming to make them as accessible as consumer electronics.

The challenge

Supply chain risks and slow iteration cycles threaten research progress in chip-based technologies

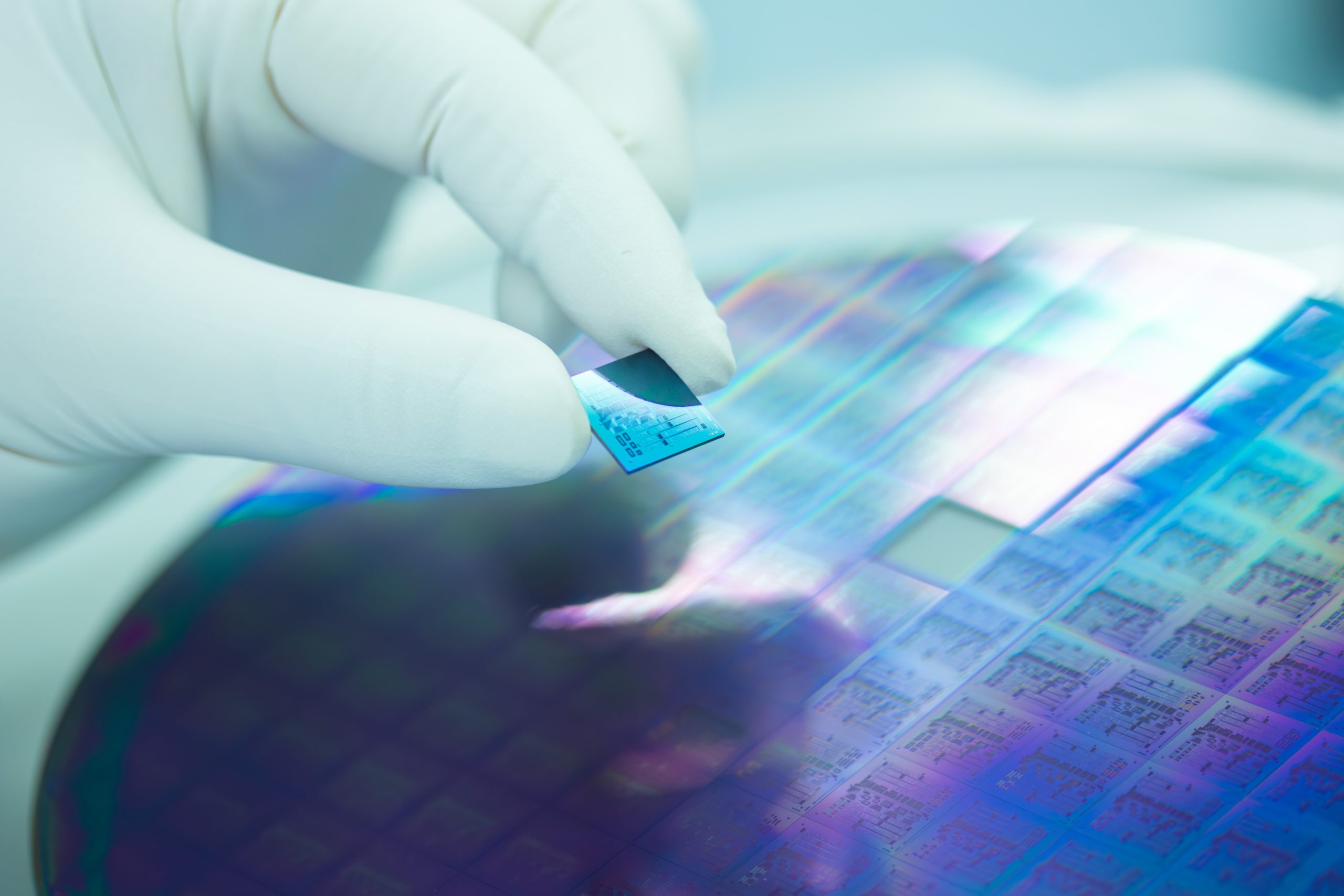

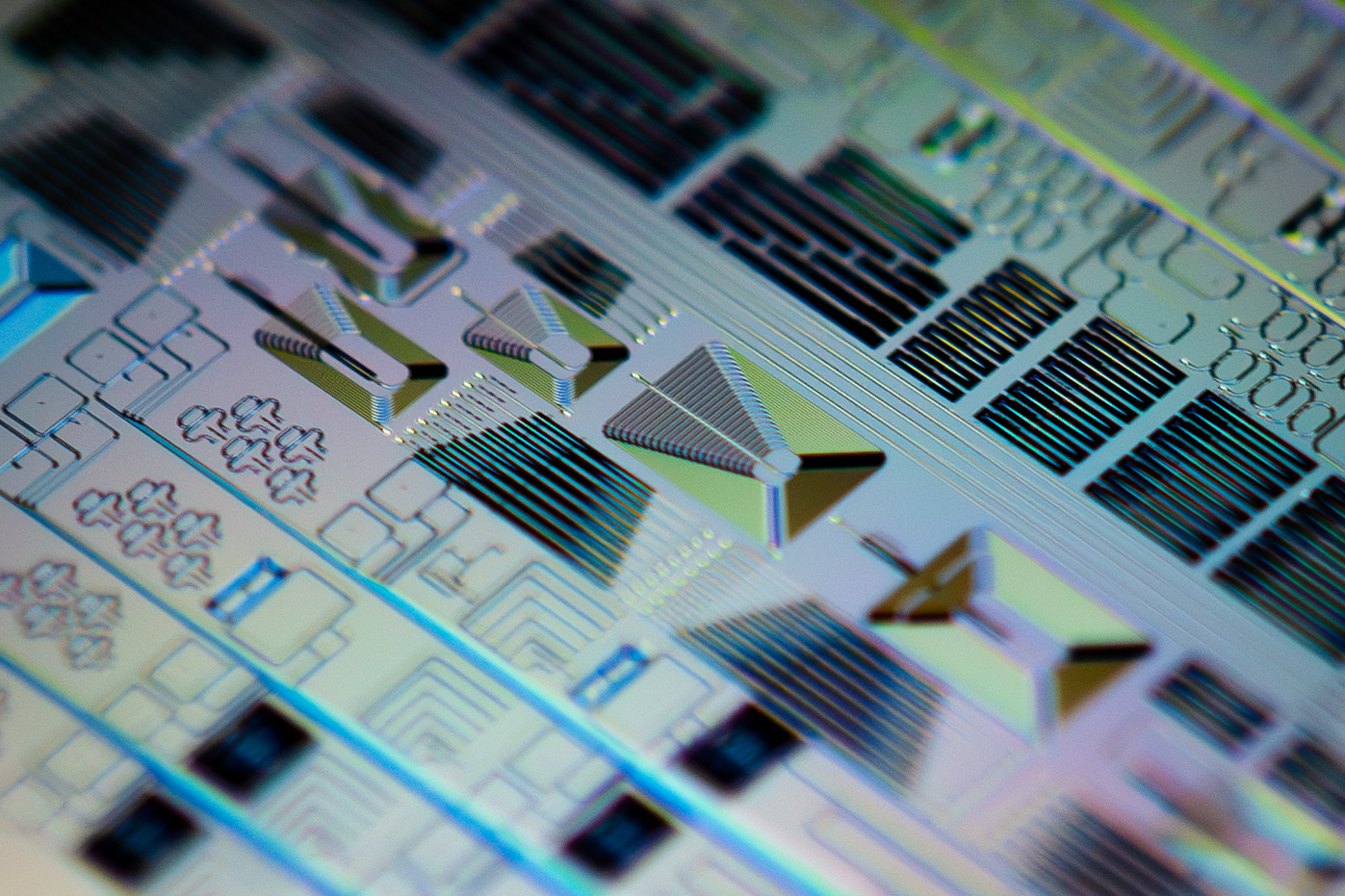

At COMBS, we are integrating the optical frequency comb onto a chip the size of a fingernail – called microcombs – targeting the size and cost of modern electronics.

We currently have different ‘flavours’ of combs-based technologies – from benchtop laser systems to microchips – and the Infrastructure Committee provides our Centre members with training and support to use this technology.

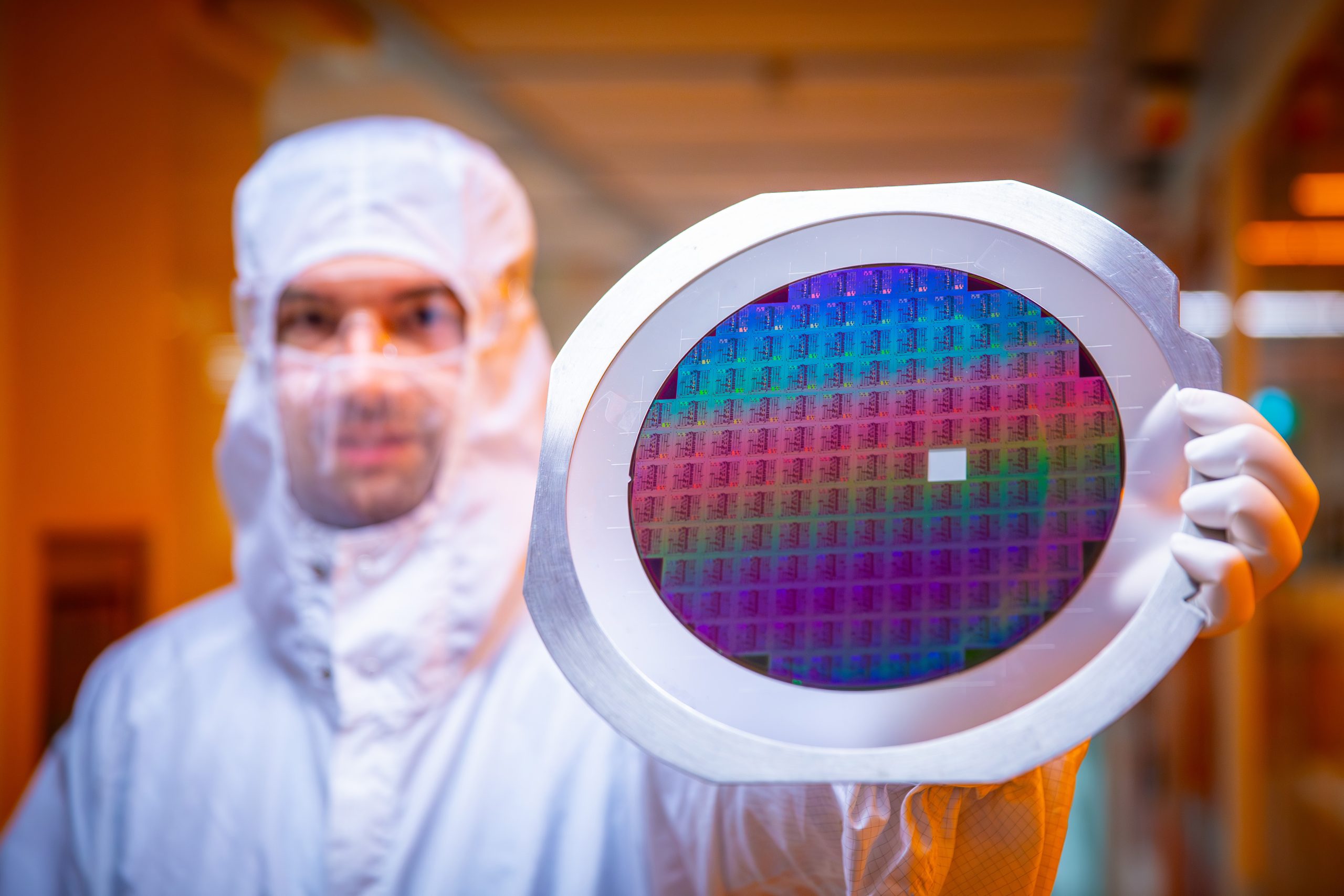

Beyond training, is developing scalable design practices, securing diverse supply chains for chips (as was exposed during COVID-19), and working toward manufacturability in industrial foundries.

Without this foresight, Australia is vulnerable to supply chain disruption, and slow 6–9-month chip design cycles, both significantly slowing research progress.

At COMBS, we can make these chips ourselves, or with some of our most trusted international partners to test identical designs across platforms to compare performance and reduce risk. Image: Peter Thurgood

Our response

Building secure, scalable supply chains through with high-quality partners

To future-proof our combs-based technology, the Infrastructure Committee is proactively diversifying fabrication sources to accelerate development and ensure long-term accessibility.

We can make these chips ourselves, or with some of our most trusted international partners to test identical designs across platforms to compare performance and reduce risk.

Rather than waiting months for each iteration, we now design in parallel across multiple foundries, accelerating progress.

We are also developing in-house fabrication to enable rapid prototyping, cutting iteration cycles from months to weeks.

A multi-supplier approach allows faster iteration – reducing wait times from 6–9 months to a matter of weeks – dramatically improving our research progress. Image: Peter Thurgood

The results and current progress

Faster design chip cycles and a stronger global network for research progress

We have received two batches of chips from different suppliers – one performing as expected, the other requiring modifications. This highlights the value of parallel supply chains and an iterative design process.

By resolving design issues early, our goal is for COMBS researchers to get functional chips the first time.

A multi-supplier approach allows faster iteration – reducing wait times from 6–9 months to a matter of weeks – dramatically improving our research progress.

In this way, the Infrastructure Committee is equipping our researchers with the skills to engage global foundries, ensuring COMBS technology remains scalable and market ready.

By strengthening our supply chain, COMBS is laying the groundwork for microcombs to become as cost-effective, scalable and manufacturable as modern consumer electronics.

We currently have different 'flavours' of combs-based technologies – from benchtop laser systems to microchips. Image: Peter Thurgood